Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LBW2200PB

Brand: WGM

Type: Insulating Glass Production Line

Certification: UL

Structure: Vertical

Control System: PLC

Condition: New

Color: OEM

Washing Glass Thickness: 3-15mm

Model: LBW2200PB

Compressed Air: 0.8/min

Length: 21300mm

Width: 2800mm

Packaging: plywood pallet ,plastic film, wooden package for exporting

Productivity: 650-700units/8hours

Transportation: Ocean,Land,Air

Place of Origin: SHANDONG, CHINA

Supply Ability: 220sets/year

Certificate: ISO-9001/CE/SGS/UL/CSA

HS Code: 84649019

Port: QINGDAO PORT

Payment Type: L/C,T/T,D/P,Western Union

Incoterm: FOB,CFR,CIF,EXW

2.2m Auto-Insulating Glass Outside Assembly Production Line

LBW2200PB Auto-Insulating Glass Outside Assembly Production Machine is a high-efficiency insulating glass processing equipment. This line is approved the Europe CE certification and China ISO-9001 standard and satisfy all aspects of customers’ demands with advanced technology, high production efficiency and complete functions. It is a better mass production equipment to produce insulating glass with high automatic degree, high efficiency, easiness of operation and maintenance.

1) The entire machine’s operation uses the man-machine contact surface (it has Chinese and English languages):

Operates direct viewing and convenient, the running status is dynamic demonstration, the frequency conversion velocity modulation; the maximum speed may amount to 45 meters/Minute.

2) High production efficiency: The big glass can move at the full speed, the small glass is possible to stop in storage area, and stay at the storage area temporarily, also the clean glass may input continuously.

3) Conserves energy interrupted type automatic operation system:

Entire machine uses the energy conservation interrupted type automatic operation system, when glass movement to the photoelectric sensor of the end of the input conveyor, the brush, the water pump, the air blower will be start automatically, when the production is interrupted, the brush, the water pump, the air blower will automatically stop, the section of the equipment which was occupied moves in full speed, other parts which do not work are at the intelligence dormant state, so it is energy saving.

The back board is high density board with film

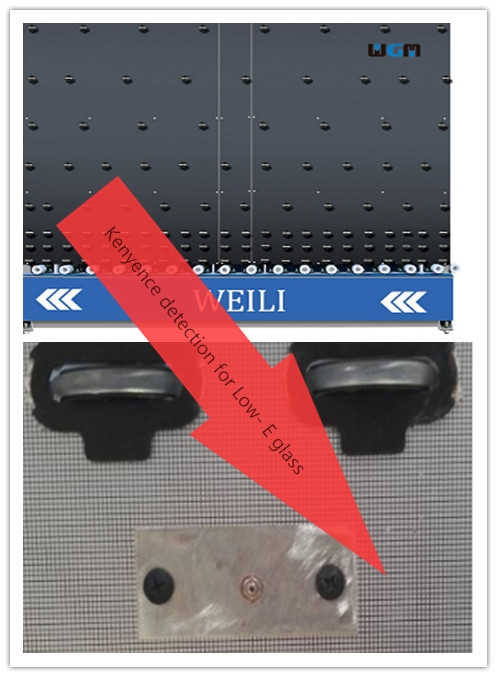

4) LOW-E glass automatic diagnosis system: it can easily know whether low-E glass putting is right or not. When is wrong, the alarm will raise the alarm, and worker can change it immediately. This system prevents the membrane of coating glass (especially the LOW-E glass) from being destroyed, the glass input conveyor station is loaded with the coating glass automatic diagnosis system, fully guaranteed the correct washing and covering of the coating glass.

Low-E glass automatic diagnosis system

5) Washing part and drying part:This part has three pairs of brushes (the material is high -temperature nylon wire ) and a pair of sponge roller. The brushes are driven by three synchronous motors separately and the movement is stable. Three pairs of tubular rollers type of hair brushes, use High Temperature Resistant and soft nature hair brush, fully guaranteed the coating glass especially the LOW-E glass layer stratification can’t be destroyed.

Brushes (high-temperature nylon wire)

Bearing is SKF from Sweden

Can automatically adjust space of drag roller according to glass thickness

Stainless steel wind knife

Outside assembly section

This section was our new design ,it can improve efficiency than assembly inside,especially to avoide the malposition questions between two or three glasses.

These two wheels are controlled by Airtac cylinder. and they can easily push the glass tightly together.

Technical parameter

| Power Supply | 380V/50HZ 37.5Kw |

| Dimension(LxWxH) | 21300x2800x3300mm |

| Production quantity | 650-700IG units/8hs |

| Max Glass Size | 2200x3000mm |

| Min Glass Size | 350x400mm |

| Washing Glass Thickness | 3-15mm |

| Washing Glass Speed | 0-10m/min |

| Insulating Glass Thickness | ≤48mm |

| Transmission Glass Speed | 0-45m/min |

| Compressed Air: | 800L/min |

| Air Pressure: | 0.7Mpa |

| Environment Temperaturer | 7~50℃ |

| Brush | 6 pieces, include 3 LOW-E brushes |

Other related items of our company:

1. Insulating Glass Production Line

2. Low-E Coating Remover Machine

3. LOW-E Coating Remover Machine

4. Aluminum Spacer Bar Bending Machine

5. Glass Washing Machine

Product Categories : Insulating Glass Production Line > Outside Assembly Flat Press Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.